HP প্রিন্টার ফিউজারের জন্য অপরিহার্য রক্ষণাবেক্ষণের টিপস

ফিউজার অ্যাসেম্বলি আপনার HP প্রিন্টারের একটি গুরুত্বপূর্ণ উপাদান, যা তাপ এবং চাপের মাধ্যমে কাগজে টোনার স্থায়ীভাবে আবদ্ধ করার জন্য দায়ী। সঠিক এইচপি ফিউজার রক্ষণাবেক্ষণ সম্পর্কে জ্ঞান অর্জন করা ফিউজারের আয়ুকে উল্লেখযোগ্যভাবে বাড়িয়ে তুলতে পারে, মুদ্রণের গুণমান উন্নত করতে পারে এবং সময়ের সাথে সাথে প্রতিস্থাপনের খরচ উল্লেখযোগ্য হারে কমাতে পারে। আসুন আপনার ফিউজারের দীর্ঘস্থায়ীত্বকে সর্বাধিক করার জন্য ব্যাপক কৌশলগুলি নিয়ে আলোচনা করি যখন এটি সর্বোত্তম কর্মক্ষমতা বজায় রাখে।

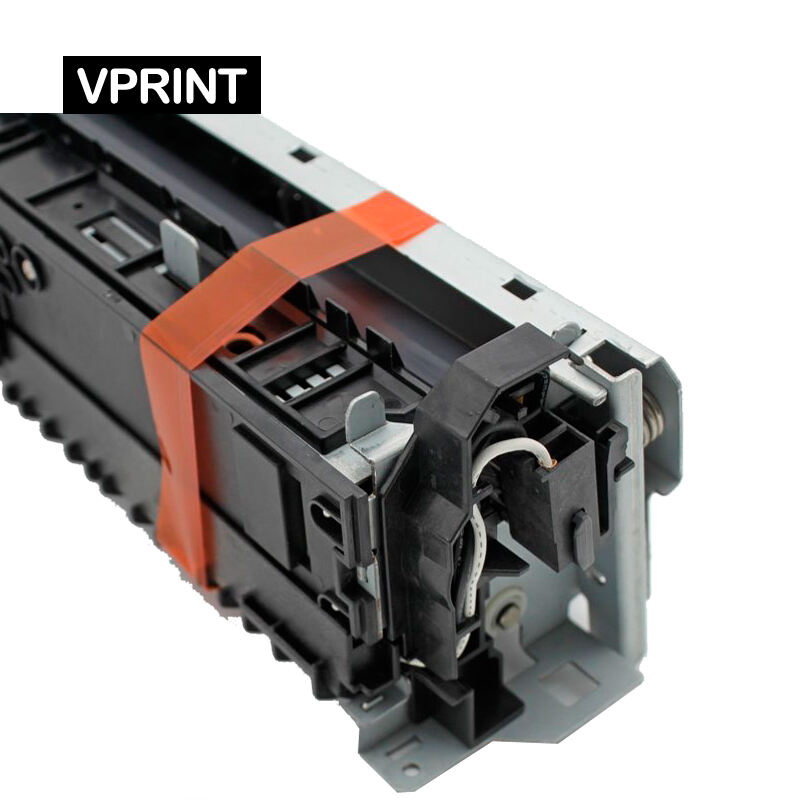

আপনার HP ফিউজারের উপাদানগুলি সম্পর্কে বুঝতে

প্রধান ফিউজার উপাদান এবং তাদের কার্যাবলী

HP ফিউজার অ্যাসেম্বলিতে কয়েকটি গুরুত্বপূর্ণ উপাদান একসাথে কাজ করে। এর প্রধান উপাদানগুলির মধ্যে রয়েছে হিটিং এলিমেন্ট, চাপ রোলার এবং থার্মিস্টর। টোনার আঠালো হওয়ার জন্য প্রয়োজনীয় নির্ভুল তাপমাত্রা বজায় রাখে হিটিং এলিমেন্ট, আর কাগজ এবং উত্তপ্ত উপাদানগুলির মধ্যে ধ্রুবক সংস্পর্শ নিশ্চিত করে চাপ রোলার। থার্মিস্টর অতিরিক্ত তাপ রোধ করে এবং মুদ্রণের গুণমান বজায় রাখে।

ফিউজার ক্ষয়ের সাধারণ লক্ষণ

ফিউজারের ক্ষয়ের প্রাথমিক সতর্কতামূলক লক্ষণগুলি চিনতে পারলে আগাম রক্ষণাবেক্ষণ করা সম্ভব হয়। কুঁচকে যাওয়া পৃষ্ঠা, টোনার মলিন হওয়া বা কাগজ আটকে যাওয়ার মতো লক্ষণগুলির প্রতি নজর রাখুন। মুদ্রণের সময় অদ্ভুত শব্দ বা পৃষ্ঠার বিভিন্ন অংশে মুদ্রণের গুণমানে অসঙ্গতি প্রায়ই ফিউজারের সমস্যা হওয়ার ইঙ্গিত দেয়। এই সূচকগুলির নিয়মিত পরীক্ষা করে অপ্রত্যাশিত ত্রুটি রোধ করা যায় এবং উপাদানটির আয়ু বাড়ানো যায়।

প্রতিরোধী রক্ষণাবেক্ষণের পদক্ষেপ

নিয়মিত পরিষ্কারের প্রক্রিয়া

HP ফিউজার রক্ষণাবেক্ষণের জন্য একটি পদ্ধতিগত পরিষ্করণ সূচি বাস্তবায়ন করা খুবই গুরুত্বপূর্ণ। টোনার এবং কাগজের ধুলো জমা দূর করতে মাসিকভাবে অনুমোদিত পরিষ্করণ শীট ব্যবহার করুন। পরিষ্কার করার সময়, সংবেদনশীল উপাদানগুলির ক্ষতি রোধ করতে প্রিন্টারটি সম্পূর্ণরূপে ঠাণ্ডা হয়েছে কিনা তা নিশ্চিত করুন। ফিউজারের পৃষ্ঠের ক্ষতি হতে পারে এমন তীব্র রাসায়নিক বা ঘষা উপকরণ ব্যবহার এড়িয়ে চলুন।

পরিবেশগত নিয়ন্ত্রণ

পরিবেশ ফিউজারের আয়ুর উপর উল্লেখযোগ্য প্রভাব ফেলে। আপনার প্রিন্টার এলাকায় আদর্শ তাপমাত্রা এবং আর্দ্রতার মাত্রা বজায় রাখুন। অতিরিক্ত আর্দ্রতা কাগজের আকার বৃদ্ধি এবং অনিয়মিত খাওয়ানোর কারণ হতে পারে, যেখানে অত্যন্ত শুষ্ক অবস্থা স্ট্যাটিক বিদ্যুৎ জমা হওয়ার কারণ হতে পারে। 45-55% আপেক্ষিক আর্দ্রতা বজায় রাখতে ডিহিউমিডিফায়ার বা হিউমিডিফায়ার ব্যবহার করার বিষয়টি বিবেচনা করুন।

অপারেশনাল বেস্ট প্র্যাকটিস

কাগজের নির্বাচন এবং পরিচালনা

HP ফিউজার রক্ষণাবেক্ষণের জন্য উপযুক্ত কাগজের প্রকার এবং ওজন ব্যবহার করা অত্যন্ত গুরুত্বপূর্ণ। আপনার প্রিন্টার মডেলের জন্য HP-এর স্পেসিফিকেশন অনুযায়ী কাগজ সর্বদা নির্বাচন করুন। একাধিক কাগজ একসাথে খাওয়ানো রোধ করতে লোড করার আগে নিয়ন্ত্রিত পরিবেশে কাগজ সংরক্ষণ করুন এবং কাগজগুলি আলাদা করে নিন। মুদ্রণ প্রক্রিয়ার সময় ফিউজার অ্যাসেম্বলিতে অপ্রয়োজনীয় চাপ কমাতে সঠিক কাগজ হ্যান্ডলিং সাহায্য করে।

মুদ্রণ পরিমাণ ব্যবস্থাপনা

ফিউজারের আয়ু বাড়াতে মুদ্রণ পরিমাণের কৌশলগত ব্যবস্থাপনা সাহায্য করে। অতিতাপ রোধ করতে বড় মুদ্রণের কাজগুলি একাধিক সেশনে বিতরণ করুন। ভারী মুদ্রণের সময় নিয়মিত বিরতি দিন যাতে ফিউজার স্বাভাবিকভাবে ঠাণ্ডা হতে পারে। মুদ্রণের কোটা বা উচ্চ ক্ষমতাসম্পন্ন প্রিন্টারগুলিতে উচ্চ পরিমাণের কাজ পাঠানোর ব্যবস্থা বিবেচনা করুন।

পেশাদার রক্ষণাবেক্ষণ পদ্ধতি

নির্ধারিত সার্ভিস সময়কাল

আপনার প্রিন্টারের ব্যবহারের ধরন অনুযায়ী নিয়মিত রক্ষণাবেক্ষণের সময়সূচী তৈরি করুন। প্রস্তুতকারকের সুপারিশকৃত সময়ান্তরে অথবা যখন প্রিন্টের পরিমাণ নির্দিষ্ট সীমা ছাড়িয়ে যায়, তখন পেশাদার সেবা গ্রহণ করা উচিত। এই সেবার সময়, প্রযুক্তিবিদগণ ফিউজার উপাদানগুলি পরিদর্শন, পরিষ্কার এবং সঠিকভাবে সমন্বয় করতে পারেন যাতে সর্বোত্তম কর্মদক্ষতা নিশ্চিত হয়।

উপাদান প্রতিস্থাপনের নির্দেশিকা

ফিউজারের ক্ষতি হওয়ার আগেই কখন ক্ষয়জনিত অংশগুলি প্রতিস্থাপন করতে হবে তা জানুন। পৃষ্ঠার সংখ্যা লক্ষ্য রাখুন এবং প্রিন্টের মান ঘনিষ্ঠভাবে পর্যবেক্ষণ করুন। প্রস্তুতকারকের নির্দেশিকা অনুযায়ী চাপ রোলার এবং পরিষ্কারের প্যাডগুলি প্রতিস্থাপন করুন। এই সহায়ক উপাদানগুলির সময়ানুবর্তী প্রতিস্থাপন ফিউজারের সঠিক কার্যকারিতা বজায় রাখতে সাহায্য করে এবং এর মোট আয়ু বাড়িয়ে তোলে।

সমস্যা নিরসন এবং পুনরুদ্ধার

ডায়াগনিস্টিক পদ্ধতি

যখন কোনও সমস্যা দেখা দেয়, তখন পদ্ধতিগত সমস্যা নিরাময়ের পদ্ধতি অনুসরণ করুন। ত্রুটির কোড পরীক্ষা করা এবং পরীক্ষামূলক প্রিন্ট করা সহ মৌলিক নির্ভরণ থেকে শুরু করুন। যেকোনো অস্বাভাবিক আচরণ বা প্রিন্ট গুণমানের সমস্যা নথিভুক্ত করুন। ফিউজার অ্যাসেম্বলিকে প্রভাবিত করছে এমন প্যাটার্ন এবং সম্ভাব্য মূল সমস্যাগুলি চিহ্নিত করতে এই তথ্য সাহায্য করে।

জরুরি প্রতিক্রিয়া প্রোটোকল

ফিউজার-সংক্রান্ত জরুরি অবস্থা মোকাবেলার জন্য স্পষ্ট পদ্ধতি তৈরি করুন। অপারেটরদের অস্বাভাবিক শব্দ শোনা গেলে বা পোড়া গন্ধ পাওয়া গেলে সঠিক বন্ধ করার পদ্ধতি সম্পর্কে প্রশিক্ষণ দিন। বিকল্প প্রিন্টার বা রক্ষণাবেক্ষণ চুক্তির মতো ব্যাকআপ পরিকল্পনা থাকা অপ্রত্যাশিত ফিউজার সমস্যার সময় ব্যবসার ধারাবাহিকতা নিশ্চিত করে।

প্রায়শই জিজ্ঞাসিত প্রশ্নাবলী

আমার কত ঘন ঘন HP ফিউজার রক্ষণাবেক্ষণ করা উচিত?

মাঝারি ব্যবহারের প্রিন্টারগুলির জন্য মাসিক নিয়মিত রক্ষণাবেক্ষণ করা উচিত, প্রতি 200,000 পৃষ্ঠা বা বার্ষিক যেকোনো একটি আগে আসে তার জন্য পেশাদার সেবা সুপারিশ করা হয়। উচ্চ-আয়তনের পরিবেশে আরও ঘন ঘন রক্ষণাবেক্ষণের প্রয়োজন হতে পারে।

আমার প্রিন্টার ঘরের ফিউজারের সর্বোত্তম কার্যকারিতার জন্য কত তাপমাত্রা বজায় রাখা উচিত?

ফিউজারের সর্বোত্তম কার্যকারিতার জন্য ঘরের তাপমাত্রা 68-75°F (20-24° C) এর মধ্যে রাখুন। উইন্ডো, এয়ার কন্ডিশনিং ভেন্ট বা তাপের উৎসের কাছাকাছি প্রিন্টার রাখা এড়িয়ে চলুন যা তাপমাত্রার স্থিতিশীলতাকে প্রভাবিত করতে পারে।

আমি কি নিজে ফিউজার অ্যাসেম্বলিটি পরিষ্কার করতে পারি?

প্রস্তুতকারক-অনুমোদিত পরিষ্কারের শীট ব্যবহার করে মৌলিক পরিষ্কার করা ব্যবহারকারীদের জন্য নিরাপদ হলেও, ফিউজারের অভ্যন্তরীণ পরিষ্কার কেবলমাত্র যোগ্য কারিগরদের দ্বারা করা উচিত। নিজে ফিউজার অ্যাসেম্বলিটি খুলে গভীরভাবে পরিষ্কার করার চেষ্টা ক্ষতি বা আঘাতের কারণ হতে পারে।