×

×

Hello friends! Ever given a thought to press brake forming of metal? It's such a cool way to form metal into various shapes and sizes! Well, today in this post we are going to learn everything about press brake metal forming and how does it work.

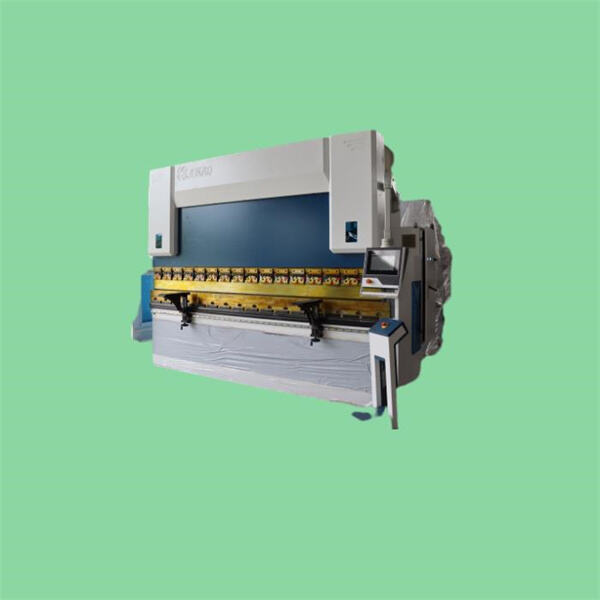

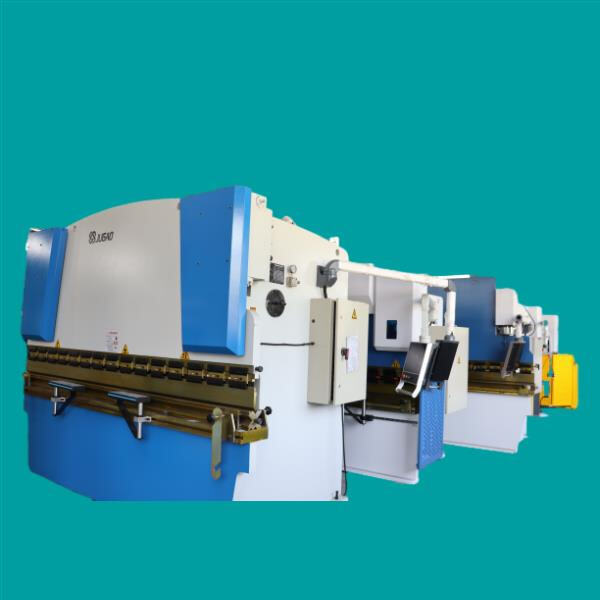

Well, let’s first discuss the art and science of tandem press brake. This metal sheet bending process occurs using a press brake, which can be automatically or manually operated. The press brake forces hard on the metal, causing it to bend in a particular way. It’s like a huge, supersized hand that can shape metal into any form you desire!

Now, we are going to talk about accuracy in press brake metal forming, meaning how careful you are. If you are precise, you do something very carefully. When we deform metal, we hope it deforms just the way we intend. It's a skill that requires practice, but with practice you can make very accurate metal shapes.

Now, on to new technologies and systems for press brake bending. The technology behind press brakes is always improving and new tools and techniques are constantly being developed to make this process even easier. For instance, there are CNC press brakes that bend metal with very high precision using computers. There are some specialty tools to help you get fun shapes and designs. These innovations have taken press brake metal forming to a level of speed and flexibility that was not possible before.

Finally, we'll look into why you’d do press brake metal forming and some of the things you can make with it in today’s modern machines. Press brake metal forming is used in many industries, including cars and airplanes. It’s a clever way to produce metal parts, and it can make everything from simple brackets to complex shapes. Companies can produce custom pieces of sheet metal in short order with press brake metal forming, and it has quickly become an integral part of the modern manufacturing process.