The Benefits of Partnering with a High-Quality Scanner Supplier

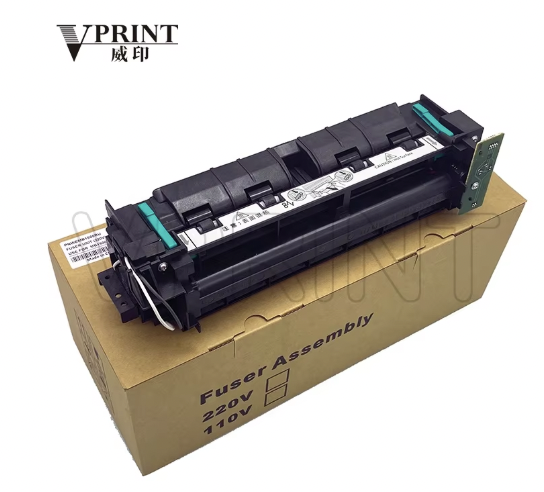

Partnering with a reliable Scanner Supplier is crucial for businesses that rely on digital document management, high-quality imaging, and uninterrupted workflow. Vprintech, founded in 2013, is a leading manufacturer and exporter of digital device spare parts and consumables, serving clients in over 80 countries. With its own factory and R&D center, Vprintech provides over 10,000 products, including Fuser units, Formatter Boards, Transfer Belts, Pickup Rollers, Toners, Drum Units, and more.

A high-quality Scanner Supplier ensures that businesses have access to reliable parts, consumables, and support services. Choosing the right supplier can improve productivity, reduce downtime, and extend the lifespan of scanning equipment.

Why Choosing a Reputable Scanner Supplier Matters

Ensuring Product Quality

A reputable Scanner Supplier guarantees high-quality parts and consumables that maintain the performance and longevity of scanners. Vprintech’s products are manufactured under strict quality control, ensuring consistency and reliability.

Reducing Operational Downtime

Reliable suppliers provide timely delivery of consumables and replacement parts, minimizing production interruptions. Vprintech’s global distribution network ensures fast shipping and support.

Technical Support and Expertise

Experienced suppliers offer technical guidance for installation, maintenance, and troubleshooting. Vprintech combines extensive industry knowledge with customer service to support clients worldwide.

Compatibility Across Brands

Vprintech provides consumables and spare parts compatible with major scanner brands, including HP, Samsung, Brother, Xerox, Canon, Ricoh, Kyocera, OKI, Pantum, Lexmark, Epson, Fujitsu, Avision, and Konica Minolta. This ensures seamless integration and reduces compatibility issues.

Key Advantages of Working with Vprintech

Extensive Product Range

With over 10,000 products, Vprintech offers comprehensive solutions for all scanner models and digital devices, including Fuser units, Formatter Boards, Transfer Belts, Pickup Rollers, Toners, and Drum Units.

Global Reach and Logistics

Serving clients in more than 80 countries, Vprintech ensures reliable delivery and supply chain management for timely support and minimal downtime.

Innovation and Patents

With over 10 years of experience and 120+ valid patents, including 3 invention patents, Vprintech continually innovates to provide safer, more efficient, and sustainable products.

Sustainable and Reliable Solutions

Vprintech focuses on producing environmentally friendly consumables and energy-efficient solutions that align with modern operational standards.

How Partnering Improves Business Operations

Enhanced Productivity

Consistent access to high-quality consumables and replacement parts reduces interruptions and improves scanning efficiency.

Cost Savings

Reliable parts extend the lifespan of equipment, reduce maintenance costs, and prevent frequent replacements.

Reduced Equipment Failures

High-quality products and timely technical support minimize the risk of equipment malfunction or downtime.

Streamlined Supply Chain

Partnering with a trusted supplier simplifies procurement, inventory management, and operational planning.

Selecting the Right Scanner Supplier

Assess Product Quality

Check certifications, quality control processes, and product reviews to ensure reliable performance.

Evaluate Technical Support

Ensure the supplier provides installation guidance, maintenance support, and troubleshooting expertise.

Review Compatibility

Confirm that consumables and spare parts are compatible with your scanner models and digital devices.

Consider Logistics and Delivery

A supplier with global reach and timely delivery ensures uninterrupted operations and minimizes downtime.

Check Innovation and Sustainability

Select a supplier that invests in R&D, innovation, and environmentally friendly products to support long-term business goals.

Best Practices When Working with a Scanner Supplier

Maintain Regular Communication

Regular updates on product availability, new innovations, and technical guidance improve collaboration and efficiency.

Monitor Consumable Usage

Track inventory, replacement parts, and toner usage to prevent delays and ensure timely ordering.

Schedule Preventive Maintenance

Use supplier guidance for scheduled maintenance to extend equipment lifespan and reduce unexpected downtime.

Stay Updated on Technology

Partnering with innovative suppliers like Vprintech ensures access to the latest advancements in scanner consumables and spare parts.

FAQ

Why is it important to work with a high-quality Scanner Supplier

A reliable Scanner Supplier ensures consistent product quality, timely support, and reduces equipment downtime, improving overall operational efficiency.

How does Vprintech support clients worldwide

Vprintech provides over 10,000 products compatible with major brands, global logistics support, technical guidance, and preventive maintenance advice.

Can partnering with a high-quality supplier reduce costs

Yes, reliable parts reduce repair and replacement frequency, extend equipment lifespan, and prevent costly downtime.

What factors should businesses consider when choosing a Scanner Supplier

Consider product quality, technical support, brand compatibility, delivery reliability, innovation, and sustainability practices.

Table of Contents

- The Benefits of Partnering with a High-Quality Scanner Supplier

- Why Choosing a Reputable Scanner Supplier Matters

- Key Advantages of Working with Vprintech

- How Partnering Improves Business Operations

- Selecting the Right Scanner Supplier

- Best Practices When Working with a Scanner Supplier

- FAQ

-

Why is it important to work with a high-quality Scanner Supplier

- A reliable Scanner Supplier ensures consistent product quality, timely support, and reduces equipment downtime, improving overall operational efficiency.

- How does Vprintech support clients worldwide

- Can partnering with a high-quality supplier reduce costs

- What factors should businesses consider when choosing a Scanner Supplier