Understanding the Essential Role of Fusing Technology in Modern Printing

The printing process might seem straightforward at first glance, but behind every crisp document lies sophisticated technology that ensures quality and permanence. At the heart of this process is the Xerox fuser, a critical component that transforms loose toner particles into durable printed images. This vital element acts as the final step in the xerographic process, permanently bonding toner to paper through a precise combination of heat and pressure.

Without a properly functioning Xerox fuser, even the most advanced printer would produce unusable output, with toner simply falling off the page at the slightest touch. Think of it as the chef that transforms raw ingredients into a perfectly cooked meal – it's the essential element that makes printing permanent and professional.

The Inner Workings of Xerox Fuser Technology

Core Components and Their Functions

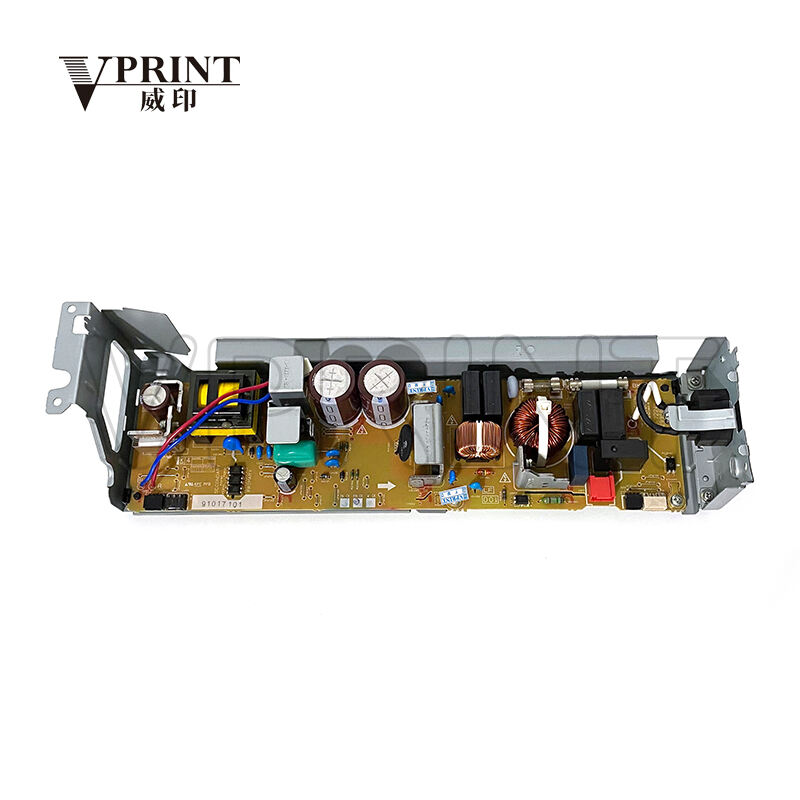

The Xerox fuser assembly consists of several sophisticated components working in harmony. The primary elements include the heat roller (also known as the fuser roller), pressure roller, heating element, and thermistor. The heat roller contains internal heating elements that maintain precise temperatures, typically between 350-425 degrees Fahrenheit. The pressure roller works in conjunction with the heat roller, creating the necessary pressure to embed toner into the paper's fibers.

Temperature control systems within the Xerox fuser are remarkably precise, utilizing thermistors and sophisticated sensors to maintain optimal heat levels. This precision ensures consistent print quality while preventing paper damage or toner-related issues. The entire assembly is engineered to operate continuously while maintaining exact specifications throughout extended print runs.

The Science Behind Fusing

The fusing process relies on a delicate balance of heat and pressure to achieve optimal results. When paper passes through the Xerox fuser, the toner particles, which are actually tiny plastic particles, melt and bond with the paper's fibers. This process happens in a fraction of a second, requiring precise timing and temperature control.

Modern Xerox fusers incorporate advanced materials science, using specialized coatings on the rollers to prevent toner adhesion while ensuring efficient heat transfer. These innovations have dramatically improved print quality while reducing energy consumption and maintenance requirements.

Maintenance and Optimization of Xerox Fusers

Essential Maintenance Practices

Proper maintenance of the Xerox fuser is crucial for consistent print quality and extended equipment life. Regular cleaning of the fuser assembly removes paper dust and toner residue that can accumulate over time. Professional technicians recommend inspecting the fuser rollers for wear or damage during scheduled maintenance intervals.

Temperature monitoring and calibration ensure optimal performance. Many modern Xerox printers include built-in diagnostics that alert users to potential fuser issues before they impact print quality. Implementing a proactive maintenance schedule can prevent costly downtime and extend the fuser's operational lifespan.

Troubleshooting Common Fuser Issues

Even well-maintained fusers can occasionally experience problems. Common issues include wrinkled output, toner not properly adhering to paper, or horizontal lines appearing on prints. Understanding these symptoms helps identify whether the Xerox fuser requires adjustment, cleaning, or replacement.

Modern Xerox printers often incorporate smart diagnostics that can detect fuser problems before they become serious. When issues arise, the system provides specific error codes and troubleshooting guidance, streamlining the maintenance process and minimizing downtime.

Environmental Impact and Energy Efficiency

Energy Conservation Features

Contemporary Xerox fusers incorporate numerous energy-saving features. Instant-on technology allows the fuser to heat up rapidly when needed while consuming minimal power in standby mode. Advanced thermal management systems optimize heat distribution, reducing overall energy consumption without compromising print quality.

The latest generation of Xerox fusers achieves significantly improved energy efficiency compared to older models. These improvements come from innovations in materials science and heating element design, resulting in faster warm-up times and lower operating temperatures.

Sustainable Design and Manufacturing

Xerox's commitment to sustainability extends to fuser design and manufacturing. Modern fusers incorporate recyclable materials and are designed for easy disassembly and refurbishment. This approach reduces waste and supports the circular economy while maintaining high performance standards.

The company continues to invest in research and development to create even more sustainable fuser technologies. These efforts focus on reducing energy consumption, extending component life, and minimizing environmental impact throughout the product lifecycle.

Future Innovations in Fusing Technology

Emerging Technologies

The future of Xerox fuser technology looks promising with several innovations on the horizon. Research into new materials and heating methods could revolutionize the fusing process, potentially leading to even lower energy consumption and faster printing speeds.

Developments in nanotechnology and advanced materials science are opening new possibilities for fuser design. These innovations could lead to more efficient heat transfer, reduced warm-up times, and improved durability of fuser components.

Integration with Smart Systems

Future Xerox fusers will likely feature enhanced integration with artificial intelligence and predictive maintenance systems. These smart features will optimize performance, predict potential issues before they occur, and automatically adjust settings for different media types.

The integration of IoT (Internet of Things) technology will enable remote monitoring and adjustment of fuser parameters, ensuring optimal performance while minimizing the need for on-site maintenance visits.

Frequently Asked Questions

How long does a Xerox fuser typically last?

The lifespan of a Xerox fuser varies depending on usage patterns and maintenance practices, but typically ranges from 100,000 to 400,000 prints. Regular maintenance and proper paper handling can significantly extend its operational life.

Can a malfunctioning fuser damage my printer?

Yes, a faulty fuser can potentially cause damage to other printer components and may result in poor print quality or paper jams. It's important to address fuser issues promptly when they're detected.

What causes most fuser failures?

Common causes of fuser failures include normal wear and tear, paper dust accumulation, improper maintenance, and using incompatible paper types. Regular cleaning and following manufacturer guidelines can prevent many common issues.

How can I tell if my Xerox fuser needs replacement?

Signs that indicate a fuser may need replacement include wrinkled prints, toner not properly adhering to paper, unusual noises during printing, and repeated paper jams. Modern Xerox printers also provide diagnostic alerts when the fuser approaches end-of-life.