What Is an HP Transfer Belt and How Does It Work?

In HP color laser printers and multifunction devices, the HP Transfer Belt is a key component that ensures vibrant, precise, and consistent color prints. While black-and-white laser printers rely on a single drum to transfer toner, color printers need a way to combine multiple colors (cyan, magenta, yellow, and black) into a single, aligned image. The HP Transfer Belt solves this problem by acting as a temporary surface for toner from each color drum, then transferring the full image to paper in one smooth step. Understanding what an HP Transfer Belt is and how it works helps users appreciate its role in print quality and maintain their printers effectively. This guide explains the basics of the HP Transfer Belt, its function in the printing process, and why it matters for reliable color printing.

What Is an HP Transfer Belt?

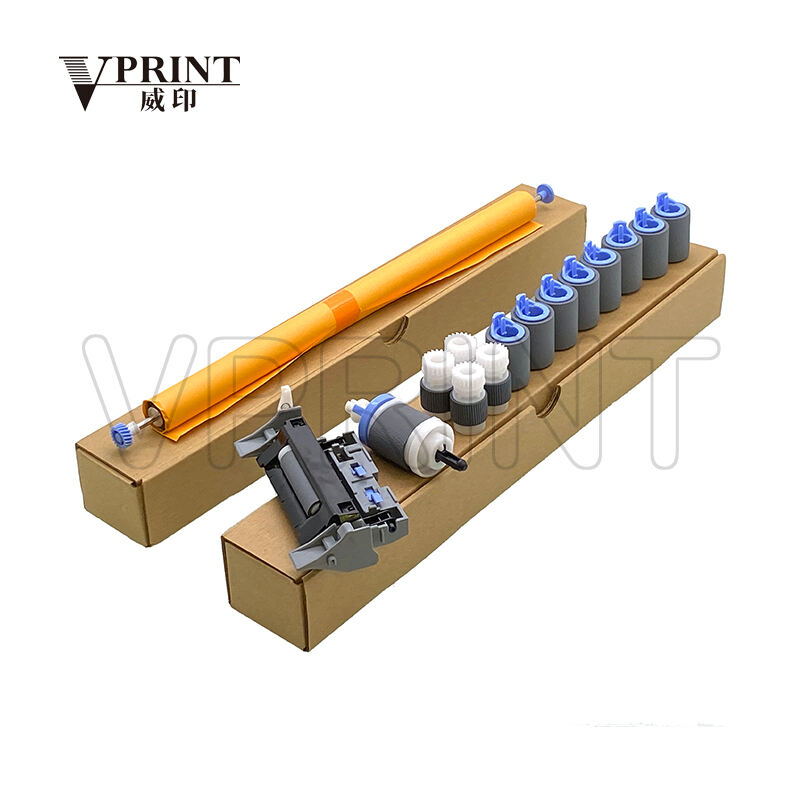

An HP Transfer Belt is a flexible, durable component found in HP color laser printers, designed to facilitate the transfer of toner from multiple imaging drums to paper. It is typically a long, thin belt made from materials like rubber or a rubber-plastic composite, often colored black or gray to avoid interfering with print colors. The belt is mounted on rollers that move it through the printer as part of the printing process.

Unlike other printer parts that focus on a single task (like a drum applying one color or a fuser melting toner), the HP Transfer Belt has a dual role: first, it collects toner from each color drum in precise alignment, and second, it transfers the combined toner image to the paper. This ensures that colors mix correctly, text lines up perfectly, and the final print matches the digital original.

HP designs Transfer Belts specifically for their printer models, ensuring compatibility with the printer’s drum system, roller speed, and electrical charging mechanisms. This customization is why genuine HP Transfer Belts are recommended—they work seamlessly with the printer’s other components to deliver consistent results.

The Role of the HP Transfer Belt in the Printing Process

To understand how the HP Transfer Belt works, it helps to break down the color laser printing process, where the belt plays a critical middle role. Here’s a step-by-step look at its function:

Step 1: Toner Application to the Transfer Belt

Color laser printers use four imaging drums—one for each primary color: cyan (blue), magenta (red), yellow, and black (often called CMYK). Each drum is charged with static electricity to attract its specific toner color. As the HP Transfer Belt moves past each drum, the following happens:

- The printer’s control system activates each drum in sequence, transferring its toner to the belt in the shape of the desired image or text. For example, the cyan drum adds blue toner where needed, followed by magenta for red, yellow for bright tones, and black for text or dark details.

- The Transfer Belt itself is charged with an opposite static charge to the toner, which pulls the toner from the drums and holds it in place. This static attraction ensures the toner sticks to the belt without smudging as it moves to the next drum.

The key here is precision: the belt must move at exactly the right speed, and each drum must apply toner in the correct position. This alignment ensures that when all colors are combined, they form a sharp, accurate image.

Step 2: Aligning Colors for a Unified Image

After collecting toner from all four drums, the HP Transfer Belt holds a complete, full-color image made of tiny toner particles. The belt’s surface is smooth and evenly charged, so the toner remains in perfect alignment—no shifting, smudging, or mixing before it reaches the paper.

This alignment is crucial for color accuracy. For example, to create a purple area, the belt must hold cyan and magenta toner in the same spot so they mix when printed. If the belt moves too fast or slow, or if its surface is uneven, the colors will misalign, creating a blurry or streaky result. HP Transfer Belts are engineered to maintain consistent speed and charge, ensuring colors stay in place until they’re transferred to paper.

Step 3: Transferring the Image to Paper

Once the full-color image is formed on the HP Transfer Belt, the belt moves to meet the paper. Here’s how the final transfer happens:

- The paper is fed into the printer and passes between the Transfer Belt and a “transfer roller” located behind the paper.

- The transfer roller applies a strong electrical charge to the back of the paper, which is stronger than the charge holding the toner to the belt. This charge pulls the toner from the belt onto the paper, transferring the full-color image in one pass.

- After the toner is transferred to the paper, the paper moves to the fuser, where heat and pressure melt the toner, making it permanent.

The HP Transfer Belt then continues rotating, ready to collect the next image from the drums. This cycle repeats for each page, with the belt ensuring consistent toner transfer every time.

Key Features of HP Transfer Belts

HP Transfer Belts are designed with specific features to perform their role effectively. These features contribute to their reliability and impact on print quality:

Static Charge Control

HP Transfer Belts are coated with materials that hold a consistent static charge, critical for attracting and holding toner. This charge is carefully calibrated to be strong enough to pull toner from the drums but weak enough to release it to the paper when the transfer roller applies its charge. Without precise charge control, toner would either fall off the belt or stay stuck to it, ruining prints.

Durable, Smooth Surface

The belt’s surface must be smooth to prevent toner from smudging or sticking unevenly. HP uses high-quality rubber or composite materials that resist scratches, cracks, and wear, even after thousands of prints. A smooth surface ensures toner applies evenly, avoiding streaks or patches in prints.

Precision Movement

HP Transfer Belts are driven by motors and rollers that keep their speed consistent. Even minor variations in speed can cause color misalignment, so the belt’s movement is synchronized with the drums, paper feed, and other components. This precision is maintained through gears, sensors, and printer software that adjust speed as needed.

Compatibility with Toner and Paper Types

HP Transfer Belts work with HP’s toner formulas, which are designed to melt and transfer at specific temperatures and charges. They also accommodate different paper types, from standard office paper to thicker cardstock and glossy photo paper, by adjusting how the belt interacts with the paper during transfer. This versatility ensures consistent results across different materials.

Why the HP Transfer Belt Matters for Print Quality

The HP Transfer Belt has a direct impact on the quality of color prints. Here’s why it’s so important:

Ensures Color Accuracy and Alignment

Without a properly functioning Transfer Belt, colors would misalign, leading to blurry images, “ghosting” (faint shadows), or incorrect color mixing. A well-maintained belt keeps colors in precise position, ensuring reds are red, blues are blue, and mixed colors (like greens or purples) look natural.

Prevents Toner Waste and Smudging

A belt with a consistent static charge and smooth surface holds toner securely, preventing it from falling off or smudging before transfer. This reduces toner waste and ensures prints have full, even color coverage without gaps or spots.

Supports High-Volume Printing

HP Transfer Belts are built to handle frequent use, making them suitable for busy offices or workgroups. Their durable materials and precision engineering allow them to maintain performance even after printing thousands of pages, ensuring consistent quality over time.

Reduces Paper Jams and Errors

A properly functioning Transfer Belt moves smoothly with the paper, reducing the risk of jams caused by misalignment or friction. This keeps the printer running efficiently and minimizes downtime.

Common Issues with HP Transfer Belts

Like all printer components, HP Transfer Belts wear down over time, leading to print quality issues. Recognizing these issues helps users address them promptly:

- Color Misalignment: As the belt wears, it may stretch or develop uneven surfaces, causing colors to shift. This appears as blurry text, shadow effects, or overlapping colors.

- Faded or Patchy Prints: A worn belt may lose its static charge in spots, failing to hold toner evenly. This leads to light areas or missing color in prints.

- Streaks or Marks: Scratches or debris on the belt’s surface can leave dark or light streaks on prints, repeating in the same position on each page.

- Error Messages: Many HP printers alert users to belt issues with messages like “Transfer Belt Error” or “Belt Life Low” when the belt nears the end of its lifespan.

FAQ

How long does an HP Transfer Belt last?

HP Transfer Belts typically last between 50,000 and 150,000 pages, depending on the printer model and usage. High-volume printing or using low-quality paper can shorten this lifespan.

Can I clean an HP Transfer Belt to fix print issues?

Light cleaning with a dry, lint-free cloth may remove surface dust or loose toner, but it won’t fix wear, scratches, or charge loss. Worn belts need replacement.

What happens if I use a non-genuine HP Transfer Belt?

Non-genuine belts may not fit properly, have inconsistent static charge, or wear quickly. This can cause poor print quality, jams, or damage to other printer components.

Do all HP color laser printers use a Transfer Belt?

Most HP color laser printers and multifunction devices use a Transfer Belt, but some smaller models may use alternative systems. Check your printer’s manual to confirm.

How do I know if my HP Transfer Belt needs replacement?

Signs include color misalignment, faded prints, streaks, or error messages. Printing a test page (via the printer’s settings) can help identify belt-specific issues.