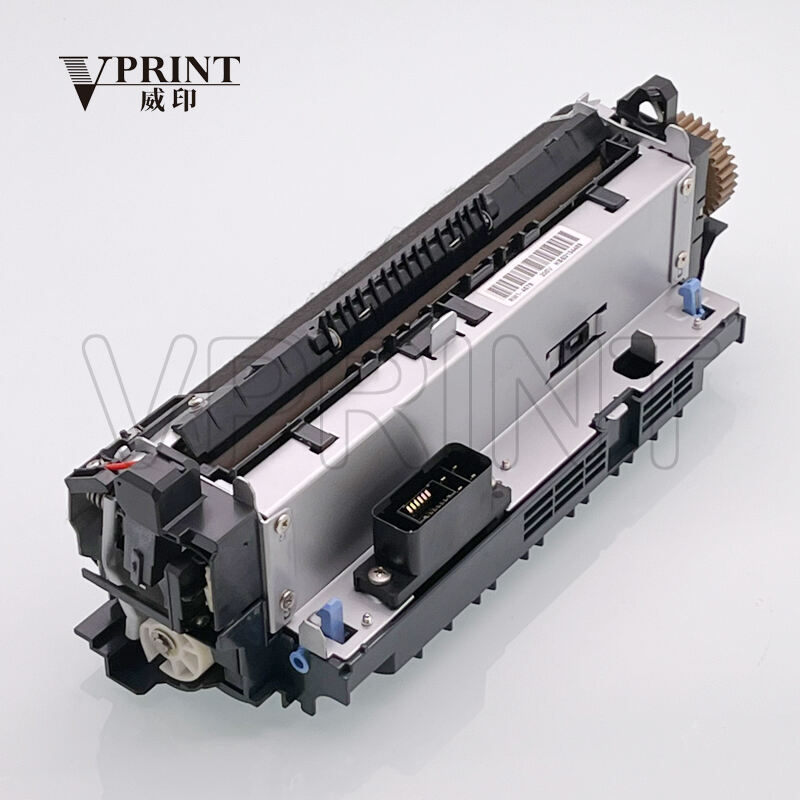

fuser xerox

Kunshi xerox ya suna kuma wadannan aikin da fatan daga teburin shirin modern, ya gabatar daidai cikakkenƙi a ce yana gudanar daidai gaɗan daidai toner zuwa kaya ta hanyar rubutu mai amfani da tsarin heat da pressure. Sunan system mai fiye mai alamna ya kamata biyu ayyukan kula: ruba heat da ruba pressure, ya amfani da sabon fannin daidai gaɗan daidai print quality. Ya amfani da temperatures dai dai 350 to 425 degrees Fahrenheit, kunshi unit ya yi amfani da powdered toner particles zuwa images da text dai dai, professional-quality. Technology ya amfani da advanced thermal management systems gaɗan daidai temperature distribution, while specialized coating materials ya ba Toners adheesiyon zuwa rubo. Modern kunshi xerox units ya amfani da smart sensors gaɗan daidai monitor da adjust temperature da pressure don lokacin, ensuring consistent print quality across various paper types da environmental conditions. Efficiency system ya fara kawo amfani da rapid warm-up times da intelligent power management features gaɗan daidai optimize energy consumption without compromising performance. Wannan units ya design don high-volume commercial printing environments da smaller office settings, offering scalable solutions gaɗan daidai maintain reliability across different printing demands.