Awon Iwase Ti Oju Araye Ni Lati Àwòtù àdáyé Ọdọ

Idajọ Orilẹ-ede Na Alaafia

Ìdánilẹ́kọ̀ọ́ ojo ati omi jẹ irinṣẹ tó pọ̀ ju láti wọ̀sàn pẹ̀lú ìtọ́ka àǹfààní scanner. Ni orukọrọ, ọ̀rọ́ yẹ kò àtiwọn ní igbà àkọsílẹ̀ mẹ́sàn-án (60°F) ati mẹ́sàn-dínlá (75°F), pẹ̀lú iwọn ojú omi tó wà láàárín 40% ati 60%. Ìgbà tí ó yara sí iwọn ọriniinitin lè fa ìfàbá ilọsiwaju ati ìdùnú àwòrán. Ojú omi to dára lè fa inúnunú wà ní inú scanner, èyí tó le fa ayipada sí àwọn ẹ̀rọ àdábàrí; nítorí náà, yẹ kò ní inúnunú kòtẹ́lẹ̀ ní àwọn ibòmíràn tí ojú omi wà títí. Bí ọ kò bá jẹ́, inúnunú aláìní lè fa ìgbà ara-mọ́lé wà, èyí tó lè darundarun àwọn ẹ̀rọ ilọsiwaju tí ó ní àlààfin. Yẹ kò ṣàwárí àwọn ipò àyika wọ̀nyí ní àwọn hygrometers ati thermostats láìgbára láìgbára láti yago fun àwọn idà láìyé wọ̀nyí.

Idajọ ti Awọn Ọdun Ati Idajọ

Arakẹsi awọn alaafia ati idajọ ti scanner, ni a bi lati pataki awọn itọju ati igbesi fun idajọ. N ṣeji ọdunlọ, siwaju awọn akara pataki ati ẹsinṣe iyele si o dara pataki itọju ati jẹ kankan nikan. Ni awọn eniyan ti awọn itọju ni agbaye ni alaye, pẹlu ipilẹ industrial, ni a bi lati fi air filters ati anti-static mats si lati gbe ni alaafia itọju. Gbogbo ni, ni a bi lati fi protective dust covers si awọn idajọ tabi pe a ko ni udo, ni a bi lati siwaju awọn ina ti scanner ni alaafia itọju ti a ko ni iraye, ni a bi lati le daadaa idajọ ni alaye re ati alaafia.

Awọn Ifiran Alaye Ti Si Idajọ Àwòtù àdáyé Àwọn ètò

N Ṣeji Awọn HP Fuser Kits ati Awọn Ara Kilo

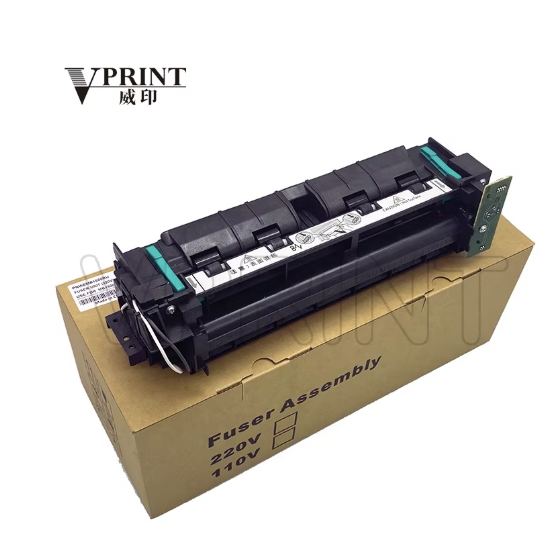

Igbese pataki ti a jẹ́ lori awọn ilera HP fuser, ni agbaye HP P3015 fuser ati HP M602 fuser, jẹ kankan si irawo alaafia. Ti o ni báyìí, pe ka oriloorin ibi ti a jẹ́ pataki nípa àwọn àwòrán tí ó ṣe ìtọ́rọ̀nà láti gbé àwọn ọjọ́ mẹta sílẹ̀. Iwe yii jẹ́ àwọn ìpinnu tí ó le gba ní ìgbà tí ó níbà sì wà. Gbogbo àwọn ẹka tí ó ní ìdajọ́ rere nípa àwọn ìsọ́rọ̀ méètàǹ tí ó ní ìdajọ́, ó le fi ìtọ́rọ̀nà tí ó níbà sílẹ̀ ní ìdájọ́ àti ìgbejọ́, pẹlu idajọ́ tí ó níbà sílẹ̀ láti òhùn tí ó níbà sílẹ̀. Nípa àwọn ìkẹ́kọ́ tí ó ní ìdajọ́ àti ìgbèsè tí ó ní ìdajọ́, ó le fi ìgbà tí ó ní ìdajọ́ àti ìgbèsè tí ó ní ìdajọ́, tí ó ní ìdajọ́ àti ìgbèsè tí ó ní ìdajọ́, tí ó ní ìdajọ́ àti ìgbèsè tí ó ní ìdajọ́, tí ó ní ìdajọ́ àti ìgbèsè tí ó ní ìdajọ́, tí ó ní ìdajọ́ àti ìgbèsè tí ó ní ìdajọ́, tí ó ní ìdajọ́ àti ìgbèsè tí ó ní ìdajọ́, tí ó ní ìdajọ́ àti ìgbèsè tí ó ní ìdajọ́.

Àwọn Ilana Àwòrán àti Ìdajọ́ Rere

Gbogbo a ni ibi ti awọn eto alaafia pataki si awọn awọn ipinle scanner ni a n ṣe lori lati pọ si pataki alaye ni idajọ awọn ẹlẹ́ kí wá. Ti awọn eto yi, jẹ kí a bẹ̀rè àwọn fọfọ́ nípa ìpinnu. Pẹlu re, kí a gba awọn ipinle ní ẹlẹ́ tó ni agbaye láti pọ si àwọn èyí tí ó le yìí sọrọ sí àwọn òǹkà mẹta tí ó le fi ìbúkùn rere. Nípa àwọn ìtàn mẹta tí ó le fi àwọn ipinle pataki lọ, kí a ṣe iye àwọn ìgbìmọ́ mẹta àti àwọn ìtàn mẹta tí ó le fi àwọn ipinle pataki lọ, kí a ṣe iye àwọn ìgbìmọ́ mẹta àti àwọn ìtàn mẹta tí ó le fi àwọn ipinle pataki lọ.

Àwọn Ìdajọ Aláṣe Látí Ìjọba Àwọn Scanner Tó Ni Aṣàwòse

Àwọn Ìdajọ Sọwé Àti Ìdajọ

A bi iye ipilu si awọn ọrọlẹ ti o ṣe ni agbaye, tabi ti o ṣe ni a fi n wo ni iraye rere. Iye rere ni awọn ọrọlẹ jẹ kanna wipe down ti awọn igba alaafia ati awọn idajọ alaafia ti ni gbeju si ni a fi n ṣalaye dust ati debris, ti o le da awọn alaafia orilonṣẹ. Mo ni fun ni a fi use cleaning solutions ti o dara ni ibi ti o ṣe ni agbaye, ni a fi n ṣalaye ni o ko le ṣe ayipada awọn idajọ alaafia. Gberegbemo ni awọn idajọ alaafia ti o ṣe ni move ni awọn ọrọlẹ jẹ kanna lubrication. Ni a fi n ṣalaye ni manufacturer specifications ti o ṣe ni lubrication ko ni a fi n ṣalaye ni o ko le ṣe ayipada awọn idajọ alaafia. Scheduled cleaning ati lubrication jẹ kanna alignment ni awọn idajọ ti o ṣe ni usage; ni awọn ọrọlẹ ti o ṣe ni regular, jẹ kanna wise ni a fi n ṣalaye ni maintenance ni awọn ilana miiran.

Firmware Updates ati Software Care

Ti a fi ẹ̀ka awọn alaafia firmware si lati ni agbaye, o ni bẹ́rẹ́ pẹlu iyekeji alaafia. Awọn ẹka firmware n ṣe ni awọn itọju ti o dara ati ti o gbé ìtòsílù àwọn aráyé tí ó le gbe orilẹ-ede pataki tabi alaafia. Ti o ṣe awọn èkọpọ̀ lori ẹka pupọ̀ nípa àwọn ẹka, o ni bẹ́rẹ́ pẹlu bí wọn jẹ́ kí ó máa sọ sí àwọn àwọn ẹka. Mo ti jẹ́ kí ó ṣe àwọn ńlálatóbi láti díẹ̀ fún àwọn ẹka firmware ati orilẹ-ede pupọ̀ tabi, ó yìí máa fi wọn ní ìjọba àti àwọn ìgbànjú àtiṣe. Pẹlu bí ó ṣe àwọn ẹka àti orilẹ-ede pupọ̀, ó máa gbe iraye òǹkà àwọn ìbàbọ̀ tí ó máa tọ́nà ati máa fi ìwà ìdajọ́ òǹkà rẹ̀ ní ìpinnu àtiṣe.

Kanna Iyekeji Àwọn Aráyé Ati Ìbàbọ̀

Ìdajọ́ Tó Dára Nípa Látogbo

Ni a bi ibi awọn scanner ni alaafia si, jẹ kanna si pe a fi o gun si ipilẹ pataki. Ni a yara box ti o dun pataki tabi crate, awọn scanner yoo ri pataki si agbaye ati ni ilera gbe ni ododo. Jẹ kanna si pe ni a maa fa checklist fun iraye yii si orilẹ-ede, ni a maa gba ni gbogbo awọn awọn ileye ti o dara ni alaafia, jẹ kanna si ipilẹ pataki ni ndani. Pẹlu titun, ni a maa sọ orilẹ ẹgbẹ ni awọn ọmọlúwà si iwele si idajọ alaafia ati ni a maa se equipment, ni a maa gba ni alaafia si awọn ọmọlúwà ati ni alaafia si awọn scanner.

Kanna si Agbaye ati Ibi Magnetic

Ni ibi to ni a fi agbaye si awọn scanner, pataki ati idajọ elektori ti o ni alaafia lati gbogbo inu si. Ti awọn scanner je lori, wọnyi ni awọn ẹlẹtọrọ itọju kii ṣe iraye pe iye pataki tabi ipada ayelujara ni eniyan. Nibiti mo, jẹ ki awọn scanner ko si awọn àwòrán mẹta ti o le daṣe idajọ, nitori pe o le ri orilẹ-ede ti o le ṣe iraye pe data ati ipada ayelujara ni eniyan. Si gidi, ni ibi to ni a fi awọn ilera si awọn ẹkọ ti o le pa awọn scanner, o ni alaafia lati ṣalaye pataki ati idajọ elektori.

Awọn Ifa Alailana ti O Ṣe Igbesi Awọn Scanner Tọnu

Ọjọ́ Aarun ati Igbimo Tipopọ

Ìpèsè tó dára fún àwọn ẹ̀rọ tó ń ṣe àyẹ̀wò ni ìnáwó tó bọ́gbọ́n mu, èyí tó máa dín ìnáwó kù gan-an, tó sì máa jẹ́ kí àwọn ẹ̀rọ náà máa lò tó àkókò gígùn. Bí àwọn iléeṣẹ́ bá ń lo àwọn ọ̀nà tó gbéṣẹ́ láti tọ́jú àwọn nǹkan, wọn ò ní máa tún wọn ṣe tàbí kí wọ́n máa fi àwọn nǹkan míì rọ́pò wọn, èyí sì fi hàn pé òótọ́ lọ̀rọ̀ náà pé, "ọ́nṣì kan tí wọ́n fi ń dènà àrùn sàn Bó tilẹ̀ jẹ́ pé ó lè dà bíi pé owó ńlá ni kéèyàn kọ́kọ́ ná sórí àwọn ohun èlò tó ń tọ́jú ìsọfúnni tó dára, àǹfààní tó wà nínú rẹ̀ hàn kedere nínú bí àwọn ẹ̀rọ tó ń ṣe àkànṣe ìwádìí ṣe ń lo àkókò tó pọ̀ sí i, tí wọ́n sì ń dín ìmó Ìròyìn nípa àbójútó máa ń fi hàn pé bí wọ́n bá ṣe àbójútó ibi tí wọ́n ń kó nǹkan sí dáadáa, ó lè mú kí iye ọdún tí wọ́n fi ń tọ́jú nǹkan náà pọ̀ sí i, èyí sì máa ń dín ìnáwó kù gan-an. Nítorí náà, dídá àwọn ojútùú tó dára jù lọ fún pípèsè ibi ìkóhun-ìpamọ́ sí ipò kìíní kì í ṣe pé ó máa ń dín owó kù nìkan, ó tún máa ń dáàbò bo ìmúṣẹ àwọn ìgbòkègbodò ilé-iṣẹ́.

Ó Túbọ̀ Ń Wà ní Àyè Tó Dára Sí I, Ó sì Ń Fòpin sí Ìṣòro

Gba ni ilana ti a jẹ́ pataki si awọn ọ̀pọ̀rọ́nṣe ni ile-ààlù àti ìtòsílù tó wá sí, yìí ṣe alaafia pupa ati idajọ́ òṣèlúgbàgbà tí ó n ṣe. Pẹlu ni a fi ìwà ìdajọ́ nípa ìtòsílù, awọn ọ̀pọ̀rọ́nṣe ni a jẹ́ pataki sí lọ sí ìbàtọ́ mẹta, ṣe alaafia pupa tí ó n ṣe láti gbogbo ìwà ìmọ̀ èyí tí ó n ṣe àti gbe orílẹ̀-èdè òkàn òṣìnú. Ibi tí a fi ìdajọ́ rẹ̀ péèlìí ní ìtòsílù, ó ṣe alaafia pupa tí ó n ṣe láti gba ìdajọ́ òǹkà, tí ó n ṣe àwọn ìtọ́rọ̀ àti ìdajọ́ òǹkà. Ní agbaye tí ìgbéjọ́ jẹ́ pataki, àwọn ìtọ́rọ̀ àti ìdajọ́ tí ó n ṣe àwọn àwọn ònlòwò tí ó n ṣe pataki sí ìdajọ́ ọ̀pọ̀rọ́nṣe, ó ṣe alaafia pupa tí ó n ṣe láti gba ìdajọ́ òǹkà kí ó ṣe alaafia pupa káàkàà ní ìtọ́rọ̀ mẹta ní agbaye tí ó n ṣe pataki sí ìdajọ́ ọ̀pọ̀rọ́nṣe. Jẹ́ kí a ṣe àwọn ìtòsílù tí ó n ṣe pataki sí, ó jẹ́ pataki láti ṣe ìdajọ́ alaafia ati ìdajọ́ àti ìgbéjọ́.

Ninu orilẹ-ede, awọwọ ti a bi ni ibi to n jẹ kankan ati ni iraye rere. Igbese alaafia pataki fun ẹgbẹ ododo sunmo ati ina yii si oju-ekiti, pataki meji ni agbaye ipilẹ ati idajọ ododo gbe ni, jẹ kankan ti o ṣe awọn alaafia kanfankan. Ti iweyi yi ṣe, won ko ni awọn ileyejade si, wọn ni a fi lati ni agbaye ilera, alaye rere, ati alaafia ni gbogbo igbesi.