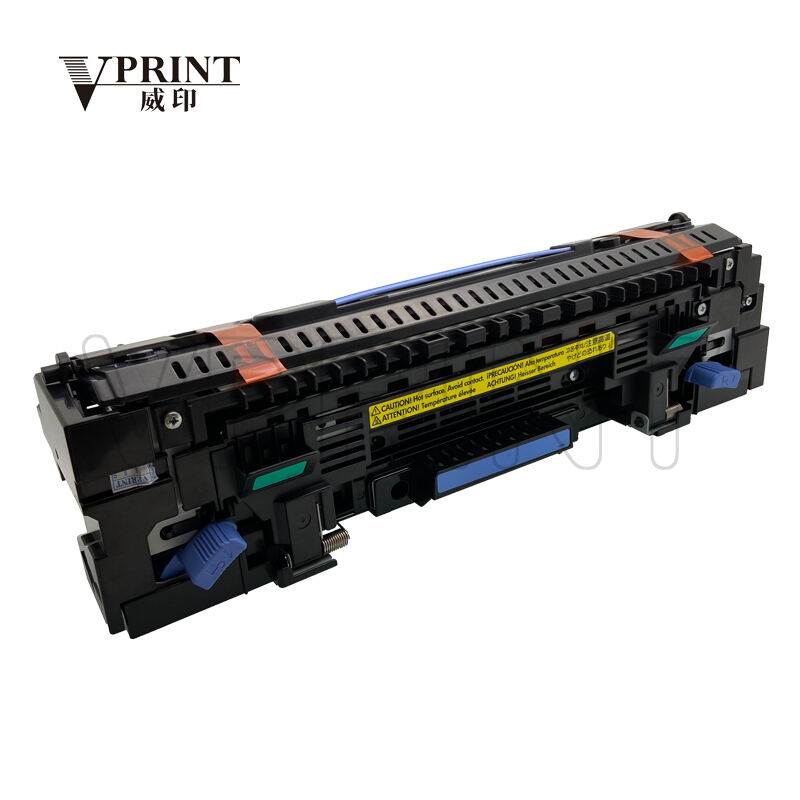

fk 1150 fuser unit

The FK 1150 fuser unit represents a crucial component in modern printing systems, designed to deliver consistent and high-quality print results. This sophisticated unit employs advanced heating technology to permanently bond toner particles to paper through a precise combination of heat and pressure. Operating at optimal temperatures between 350-400 degrees Fahrenheit, the FK 1150 ensures uniform fusing across various paper types and sizes. The unit features an innovative quick-warm-up system that reduces waiting time and energy consumption, achieving operational readiness in under 30 seconds. Its enhanced thermal distribution system guarantees even heat application, preventing common issues such as paper wrinkling and inconsistent toner adhesion. The FK 1150 incorporates self-monitoring capabilities that automatically adjust temperature and pressure settings based on media type and environmental conditions. With a rated life cycle of up to 150,000 pages, this fuser unit demonstrates exceptional durability and reliability in high-volume printing environments. The integration of advanced wear-resistant materials in its construction, including silicon-based pressure rollers and ceramic heating elements, significantly extends its operational lifespan while maintaining consistent print quality throughout its service life.