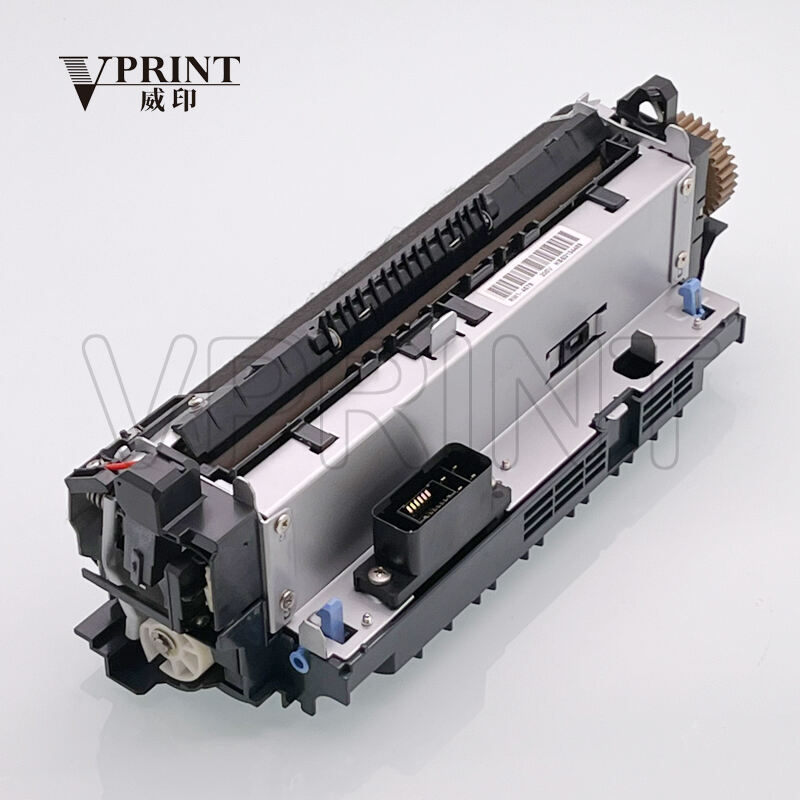

fuser xerox

The fuser xerox represents a critical component in modern printing technology, serving as the essential mechanism that permanently bonds toner to paper through a precise combination of heat and pressure. This sophisticated system consists of two main components: a heat roller and a pressure roller, working in tandem to ensure optimal print quality. Operating at temperatures ranging from 350 to 425 degrees Fahrenheit, the fuser unit transforms powdered toner particles into durable, professional-quality images and text. The technology employs advanced thermal management systems to maintain consistent temperature distribution, while specialized coating materials prevent toner adhesion to the rollers. Modern fuser xerox units incorporate smart sensors that monitor and adjust temperature and pressure in real time, ensuring consistent print quality across various paper types and environmental conditions. The system's efficiency is further enhanced by rapid warm-up times and intelligent power management features that optimize energy consumption without compromising performance. These units are designed for both high-volume commercial printing environments and smaller office settings, offering scalable solutions that maintain reliability across different printing demands.