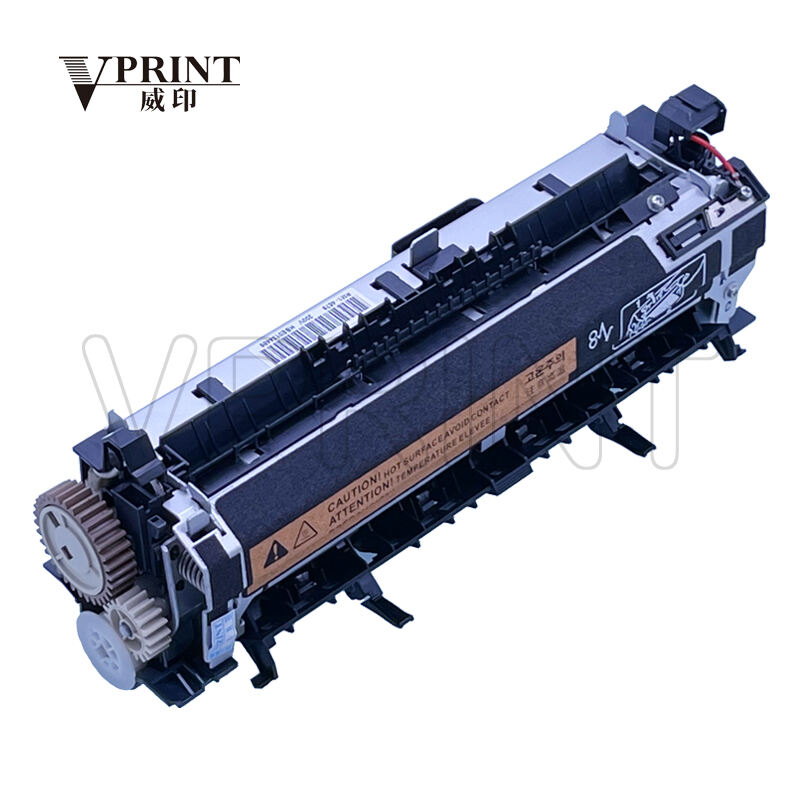

брат фузер

Елемент з'єднання Brother є ключовим компонентом у лазерних друкувальних пристроях та мультіфункціональних пристроях, відповідаючи за постійне сполучення тонера з папером шляхом точного застосування тепла і тиску. Цей складний механізм працює при тщеслідно контролюваній температурі, зазвичай між 350-400 градусами за Фаренгейтом, забезпечуючи оптимальну якість друку та тривалість. З'єднання складається з двох головних компонентів: нагрівального валка та валка тиску, які працюють разом для створення друків професійної якості. Коли папір проходить через ці валки, тепло розплавлює частинки тонера, а тиск забезпечує рівномірне розподілення та прилипнення до поверхні паперу. Сучасні з'єднання Brother мають убудовані системи термального керування, які підтримують стабільні температури протягом всього процесу друку, запобігаючи загально Known проблемам, таким як закручування паперу або неповна фузія тонера. Дизайн одиниці також включає захищаючі покриття, які запобігають накопиченню тонера та продовжують строк експлуатації. Ці з'єднання розроблені для обробки різних типів та ваг паперу, від стандартного офісного паперу до спеціальних матеріалів, що робить їх універсальними для різних потреб друку. Регулярне технічне обслуговування та правильна обробка з'єднання забезпечують оптимальну продуктивність та довгий строк служби системи друку.