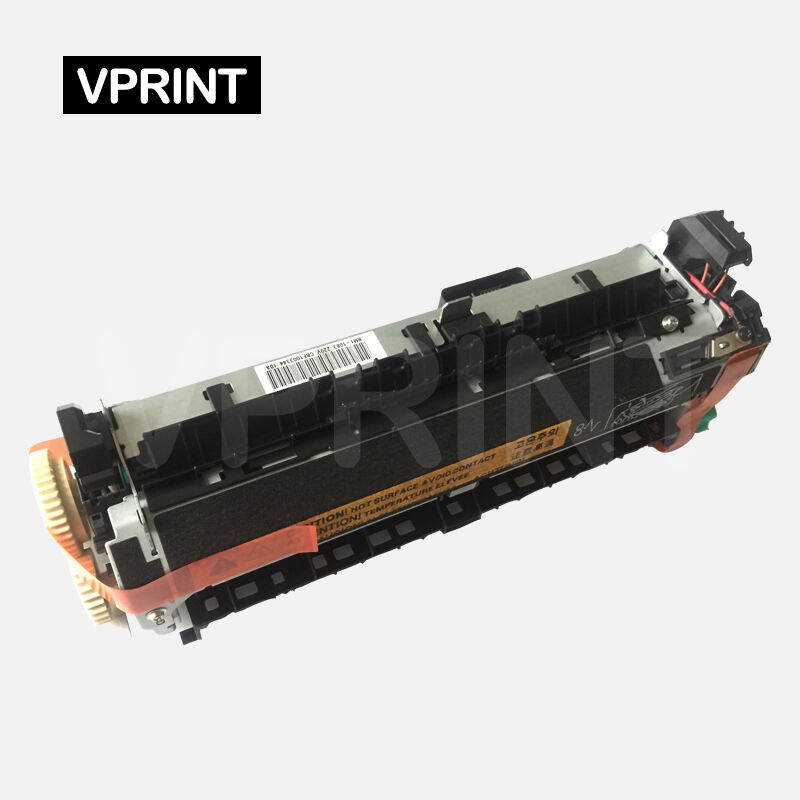

fuser unit ricoh

The fuser unit Ricoh represents a critical component in modern printing systems, serving as the essential mechanism that permanently bonds toner to paper through a precise combination of heat and pressure. This sophisticated unit consists of advanced heating elements, pressure rollers, and temperature sensors that work in harmony to ensure optimal print quality. The fuser unit maintains consistent temperatures ranging from 350-425 degrees Fahrenheit, allowing for the precise melting of toner particles. Its design incorporates innovative thermistor technology for accurate temperature control and specialized coating materials that prevent toner adhesion to the roller surfaces. The unit's versatility enables it to handle various paper types and weights, from standard office paper to specialized media, while maintaining consistent print quality. In professional printing environments, the Ricoh fuser unit demonstrates remarkable durability, capable of processing thousands of pages while maintaining consistent performance. The unit's modular design facilitates easy maintenance and replacement, minimizing printer downtime and ensuring continuous operation. Additionally, the fuser unit incorporates energy-efficient technologies that optimize power consumption during both active printing and standby modes, contributing to reduced operational costs and environmental sustainability.