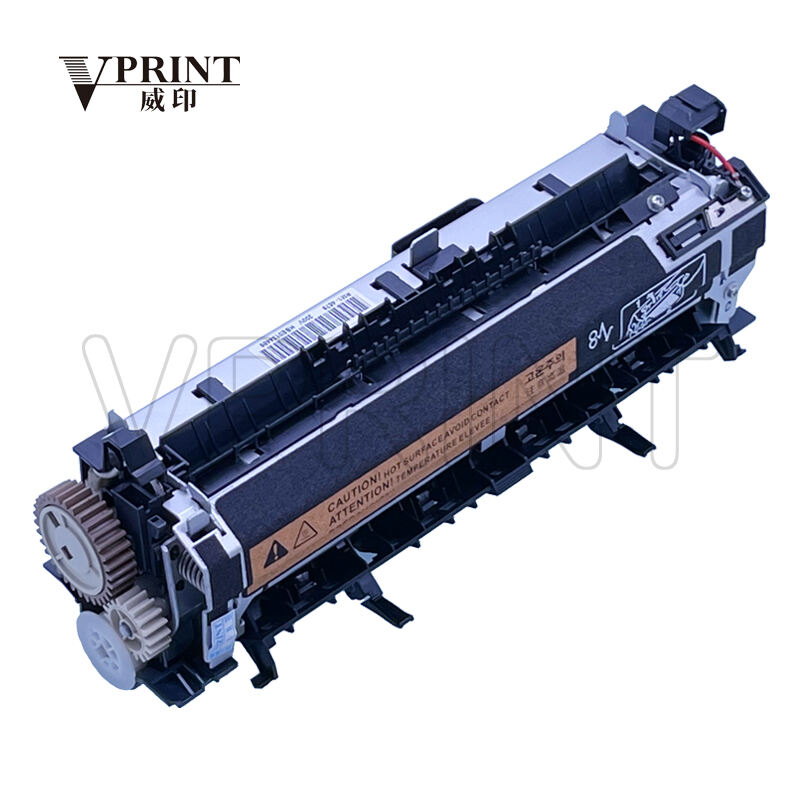

fuser unit xerox

The fuser unit Xerox is a critical component in modern printing systems that plays a fundamental role in the xerographic process. This essential device uses heat and pressure to permanently bond toner particles to paper, creating lasting, professional-quality prints. Operating at precisely controlled temperatures typically ranging from 350 to 425 degrees Fahrenheit, the fuser unit consists of two main components: a heated roller and a pressure roller. The heated roller, often equipped with internal halogen lamps or ceramic heating elements, maintains consistent temperature throughout the printing process, while the pressure roller ensures uniform contact between the paper and heated surface. Advanced sensors and thermal management systems within the fuser unit continuously monitor and adjust temperatures to maintain optimal printing conditions. The unit's sophisticated design incorporates special coatings and materials that prevent toner adhesion to the rollers while facilitating smooth paper movement. This technology enables the fuser unit to handle various paper types and sizes, from standard office paper to specialty media, ensuring consistent print quality across different applications.