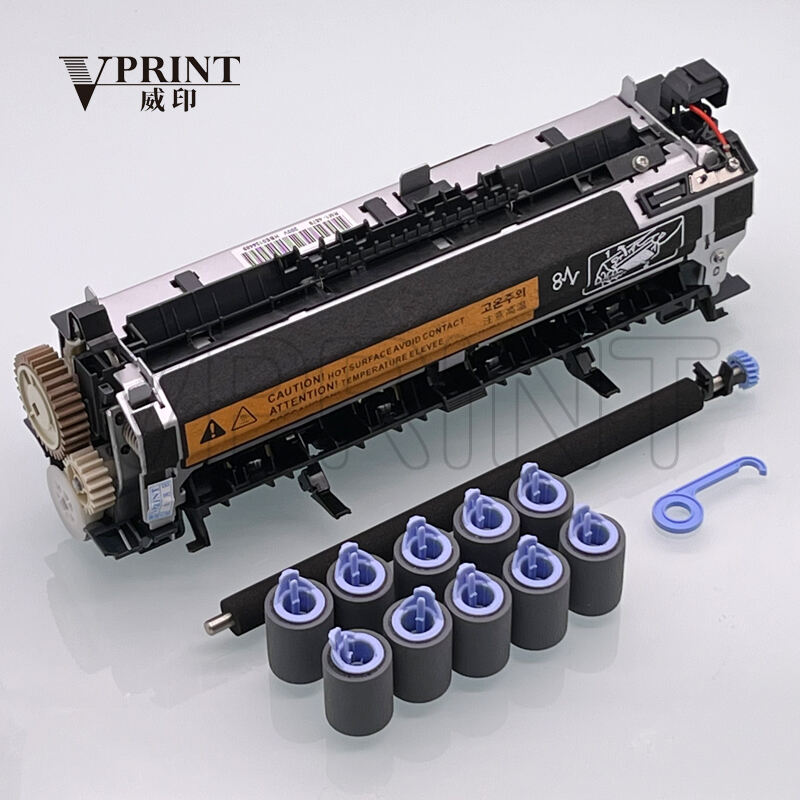

kyocera maintenance kit

The Kyocera Maintenance Kit is an essential component designed to ensure the optimal performance and longevity of Kyocera printing devices. This comprehensive kit includes crucial replacement parts such as the drum unit, transfer roller, fuser unit, and various paper handling components that naturally wear over time. Engineered with Kyocera's renowned precision technology, each maintenance kit is specifically calibrated to match different printer models, ensuring perfect compatibility and seamless integration. The kit's primary function is to maintain consistent print quality while preventing unexpected breakdowns through scheduled maintenance interventions. Professional-grade materials used in the components guarantee extended service life and reliable operation under heavy workloads. The maintenance kit's installation process has been streamlined for efficiency, allowing for quick replacement of wearing parts with minimal printer downtime. Advanced thermal management features in the fuser unit help maintain optimal operating temperatures, while specially designed rollers ensure smooth paper handling and prevent common issues like paper jams and misfeeds. This comprehensive solution addresses both preventive maintenance needs and performance optimization, making it an indispensable tool for maintaining professional print quality and operational efficiency.