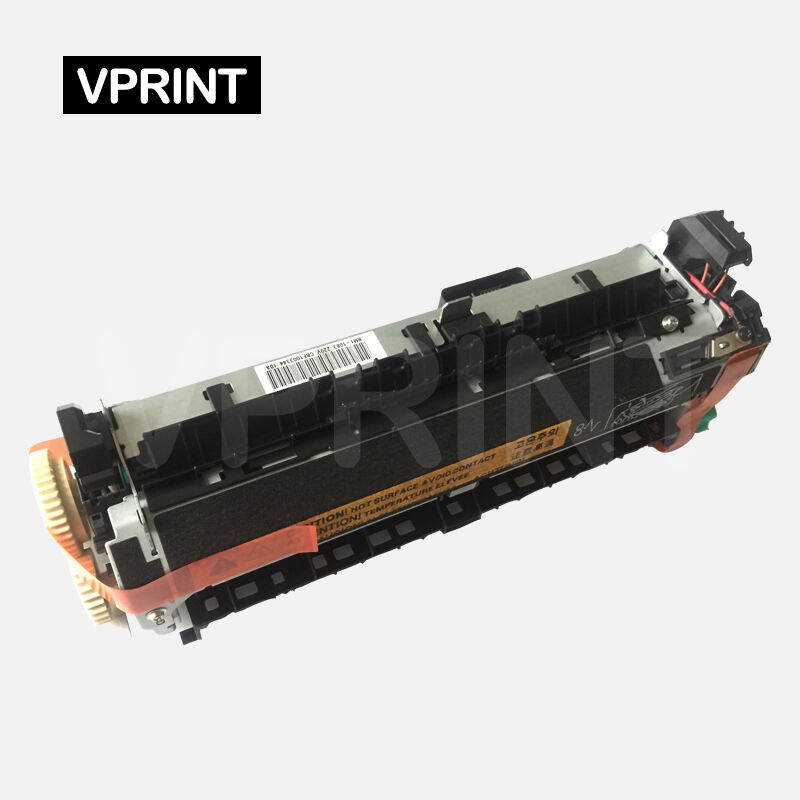

roller fuser

A roller fuser is a critical component in modern printing systems, designed to permanently bond toner particles to paper through a combination of heat and pressure. This sophisticated device consists of two primary rollers: a heated upper roller and a pressure-applying lower roller. The heated roller maintains a precise temperature, typically between 150-200 degrees Celsius, ensuring optimal toner melting and adhesion. As paper passes through these rollers, the toner particles are effectively melted and pressed into the paper fibers, creating permanent, professional-quality prints. The roller fuser employs advanced temperature control systems, utilizing thermistors and sophisticated sensors to maintain consistent heat distribution across the entire roller surface. This technology ensures uniform print quality regardless of paper type or print volume. Modern roller fusers also incorporate innovative coating technologies that prevent toner adhesion to the roller surface while maximizing heat transfer efficiency. These systems are essential in both commercial and industrial printing environments, capable of handling various paper weights and sizes while maintaining consistent print quality at high speeds.